How to Make a Garment Rack: A Guide for B2B Buyers

Are you sourcing high-quality garment racks for your business? Whether you’re a retailer or wholesaler, understanding how to make a garment rack can guide your purchasing decisions. Here, we’ll explain the essentials and why Great Shine, with its expertise in foldable garment racks, is your ideal partner.

To make a garment rack, manufacturers select materials, cut and shape components, assemble, and ensure quality. Using durable materials like stainless steel ensures racks are functional and long-lasting. Let’s explore the details and how Great Shine supports your business with OEM/ODM solutions.

Looking for a reliable supplier? Great Shine specializes in foldable garment racks tailored to your needs. Let’s break down the process and benefits of partnering with us.

Manufacturing Basics

1.1 Material Selection

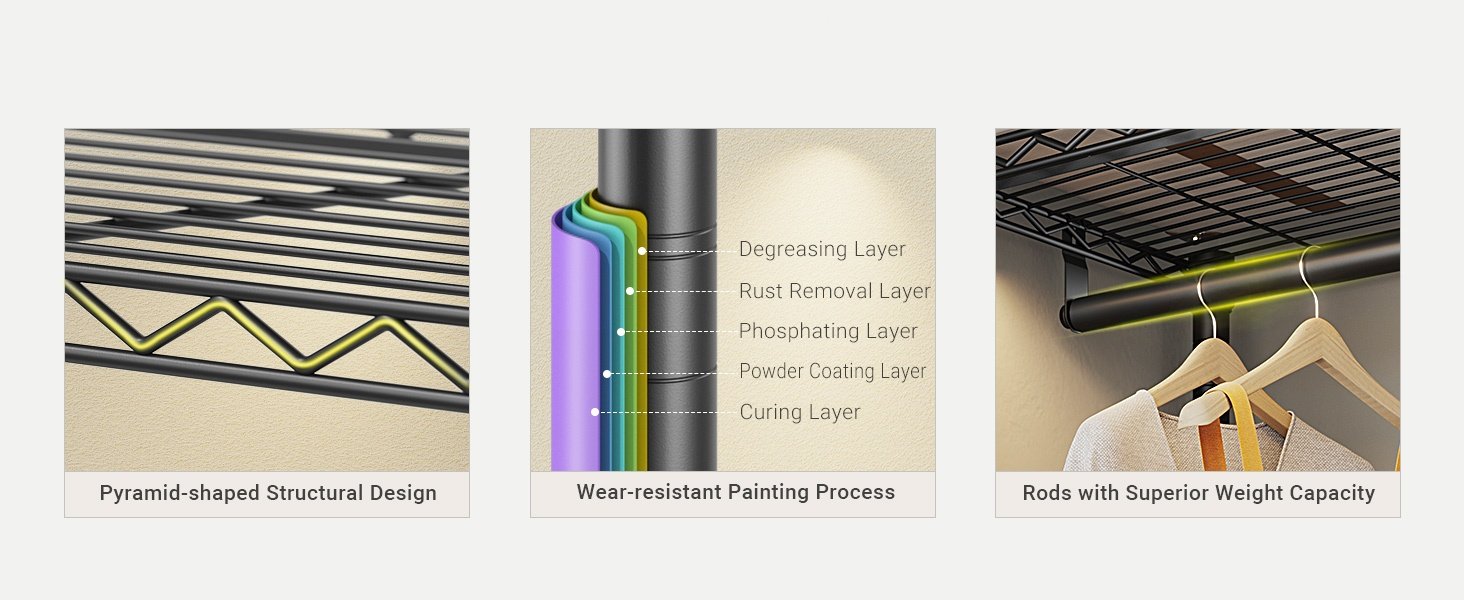

Creating a durable rack starts with materials like high-quality steel or aluminum. These ensure racks are lightweight yet sturdy, perfect for heavy loads. Foldable racks also feature:

– Hinges for folding.

– Non-slip foot caps for stability.

– Protective coatings to prevent rust.

1.2 Design and Customization

Customization is key for B2B clients, including:

– Adjustable heights.

– Modular designs for easy assembly.

– Branding options like logos or colors.

How Garment Racks Are Made

2.1 Cutting and Shaping

Precision machinery cuts and shapes components. For foldable racks, joints and mechanisms receive extra attention. Great Shine ensures every piece fits perfectly.

2.2 Welding and Assembly

Components are welded or bolted together with consistency enhanced by automation. Manual checks maintain high standards.

2.3 Surface Treatment

Racks undergo treatments like:

– Powder Coating: Scratch-resistant and smooth.

– Electroplating: Shiny and corrosion-resistant.

2.4 Quality Control

Inspections include load-bearing tests, stability checks, and surface reviews. At Great Shine, every rack meets strict standards.

Why Choose Great Shine?

3.1 Who We Are

Great Shine operates two factories with 10,000 square meters and multiple production lines. We deliver high-quality OEM and ODM solutions for businesses worldwide.

3.2 What Sets Us Apart

1. Custom Solutions: Tailored designs to match your needs.

2. High Capacity: Efficient production for bulk orders.

3. Expertise: Decades of experience.

4. Foldable Rack Specialty: Durable, space-saving designs.

3.3 Flexible Partnerships

We offer:

– OEM services for your branding.

– ODM for exclusive innovations.

Benefits of Professional Manufacturing

4.1 Quality Assurance

Reliable factories like Great Shine ensure every rack is consistent and durable.

4.2 Cost Efficiency

Eliminate middlemen and enjoy competitive pricing for bulk orders.

4.3 Fast Delivery

Our advanced facilities handle large orders quickly, whether it’s 500 or 5,000 racks.

4.4 Sustainability

Great Shine values eco-friendly materials and efficient production methods to reduce environmental impact.

Conclusion

Making a garment rack involves careful material selection, engineering, and quality control. As a professional manufacturer, Great Shine excels in producing high-quality garment racks using advanced techniques and precision. With state-of-the-art facilities and a commitment to excellence, we are ready to collaborate with you to elevate your brand through customizable, high-quality solutions. Contact us today to discuss your needs and explore how we can support your business growth.